Maintaining your refrigeration system is crucial for ensuring the integrity of perishable goods during transit. Whether you're transporting deep frozen, fresh produce, pharmaceuticals, or other temperature-sensitive products, maintaining your refrigeration system in line with the OEM’s recommendations will certainly help sustain your equipment operation at its optimum condition. Properly functioning equipment is key to delivering the product at its desired condition whilst also reducing your fuel costs and minimising costly breakdowns. In this blog, we'll explore a few essential tips to help you maintain your refrigeration system effectively.

Regular Inspections

Regular or scheduled inspections are the cornerstone for any refrigeration system maintenance. Make it a daily habit to visually inspect your refrigeration unit before each trip. Check for any signs of wear and tear, abnormal noises, leaks, or damaged components. Maybe start at the fuel tank, ensuring it is dry and the breather is clean. Work your way to the unit and check your panels are all free from damage and secure. Always make sure the unit is turned OFF at the controller if you are opening the doors to inspect fluid levels or anything mechanical. If your unit has 2-way communication, turn OFF the main controller switch. Open the doors and visually inspect the belts for tightness, look at the compressor and surrounding refrigeration lines- does it look clean? Inspect the engine, check the oil level, inspect the coolant levels. Check your microprocessor. Turn it on, are there any alarm codes? Put the units through a self diagnostic test or Pre-trip. If this is OK, load your van, trailer, container or truck.

Cleanliness is key

Keeping your refrigerated transport unit clean is essential for optimal performance. Dirt, debris, grime and unfortunately bird nests can accumulate throughout the unit. Depending on your equipment operating or travel conditions, ensure you inspect and maintain the external condition of your unit, in particular, maintain a clean condenser and/or radiator. Dusty, wet conditions can block these components and increase operating pressures and temperatures. Internally, we must also ensure the evaporator coil/s are clean. Dirty evaporator coils can restrict the airflow over your coil, reducing refrigeration capacity with possible excessive defrosting due to ice build-up. Additionally, ensure that the drain lines are clear so that water will exit quickly during defrosts and not over your load. Lastly, always ensure the controller is easily read. After-all, no one wants to set a load of fresh bananas at -16oC or set Ice-Cream to +25oC.

Proper Temperature Management:

Maintaining the correct temperature is crucial for preserving the quality of your cargo. Here are 10 quick tips for proper loading:

- Only load product in a clean trailer, container, or van.

- Precool the body before loading - refer to your companies Policy and Procedures.

- Ensure the unit setpoint is at the required load temperature.

- Ensure you load the product correctly.

- Ensure the air path can clearly discharge over the load from the unit air outlet, over the load, down the side of the load, and return from the rear of the body all the way through the pallets to the return air of the unit.

- Never load the products higher than the discharge air outlet.

- If you need to divide your load into sections, turn the plywood or corflute on an angle so as to not block the air path through the pallets.

- If you are loading multi-temperature products and are dividing the products with insulated bulkheads or walls, ensure they are secure and seal correctly at the roof, side walls and floor. Mixing air from frozen to chilled will damage loads, particularly temperature sensitive products.

- Monitor the temperature regularly and ensure no alarm codes are present before or during transit.

- In the event of an alarm, contact your manager immediately for the next course of action.

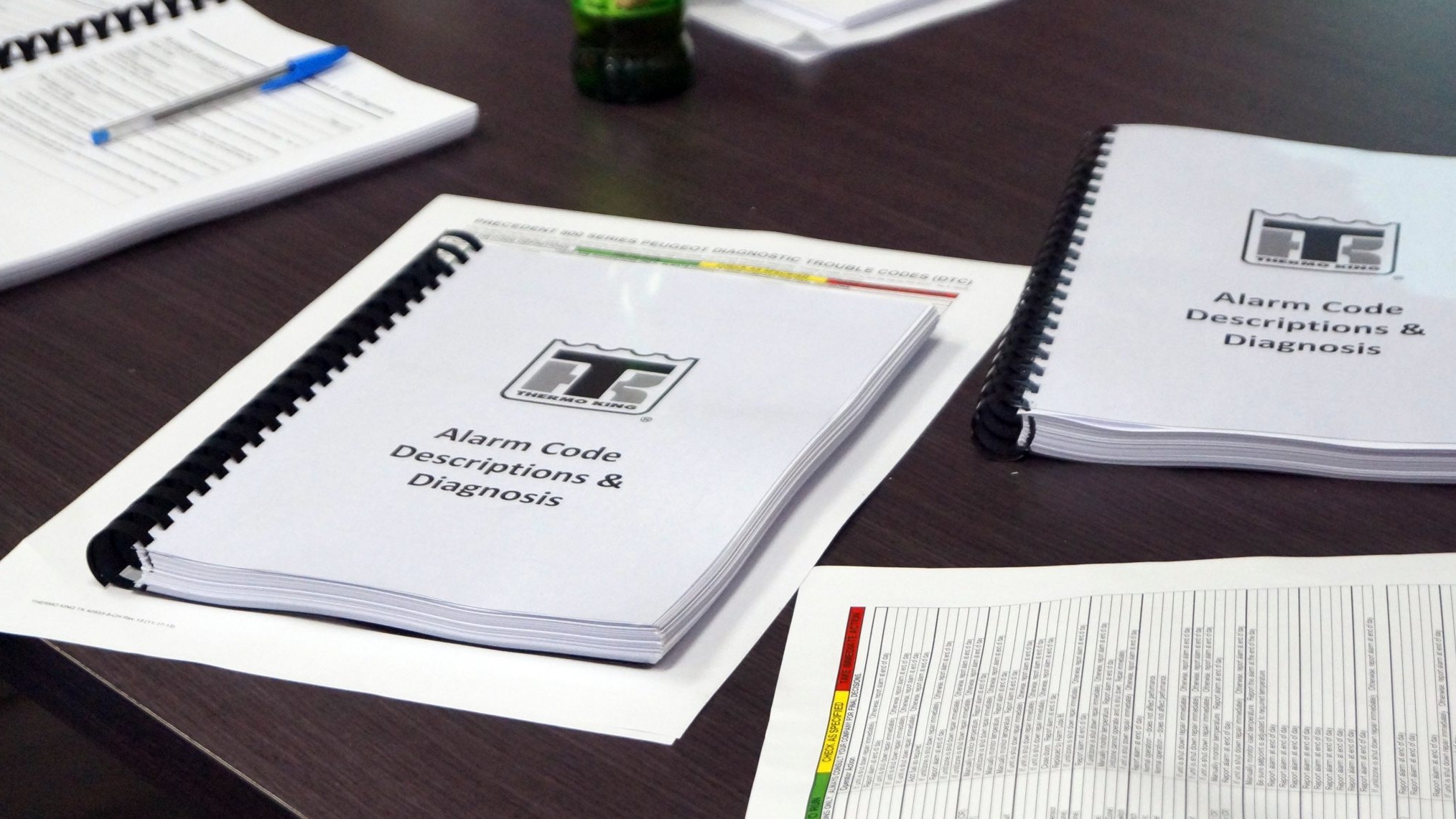

Train your drivers/operators

Properly trained drivers/operators play a significant role in maintaining the efficiency of your refrigeration system. Provide comprehensive training on how to operate the refrigeration unit correctly, including temperature control settings, loading procedures, and emergency protocols. Encourage them to report any issues or abnormalities promptly, and emphasise the importance of preventive maintenance.

Southern States Group Provides Expert Refrigeration Solutions

SSG - Southern States Group have been industry leaders in the Australian Transport Refrigeration Industry. Please contact us at any time for any of your refrigeration requirements, advice, sales, or technical support.

Our team of refrigerated transport professionals look forward to assisting you.